Our first target microbe for Mars, and how we chose it 🏗️

Goal: push the limits of science AND be practically useful

Introduction

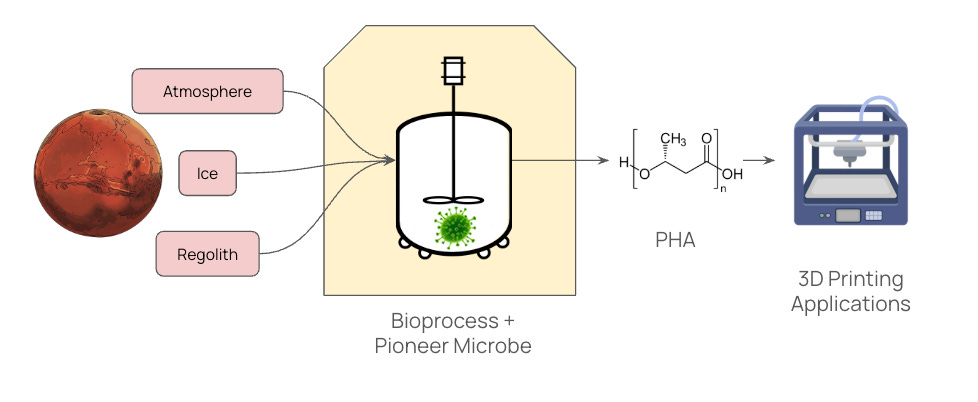

Biomanufacturing has long been attractive for Mars missions due to its potential flexibility—biology can produce everything from building materials to therapeutics. However, the sheer number of possible bioproducts has created decision paralysis and made it difficult for the field to focus on a first application. In this post, we describe our diligent process for selecting the first microbial bioprocess to develop for Mars. We focused on options that require minimal infrastructure, use only in situ Martian resources, and yield products useful to the first human mission. Today, our top candidate is a microbe that produces bioplastic entirely from Martian dirt, water, and air, using only infrastructure that fits in a refrigerator-sized box. We now have a first concrete target for engineering, as well as a framework for reasoning about future biological engineering efforts to fill greenhouses and beyond. 🚀

Our top candidate

The ideal first bioprocess for Mars would have these features:

🏗️ Minimal infastructure: A bioprocess run on Mars will need to do more with less. Less complex equipment with a smaller footprint will be easier to launch and more likely to work.

💯 100% Mars: As much as possible, the bioprocess should use raw materials from Mars as the input. Consumables that need to be brought from Earth inherently limit how much can be produced.

💪 Impactful product: Making anything using only Mars materials would be great. Even better if the product made is valuable and impactful for uses like enabling crewed missions and future terraforming efforts.

Using these goals, we imagine a setup wherein a small reactor (🏗️) can be fed with raw Mars materials: dirt; water; and air (💯), and produce bioplastics that can be turned into fibers, films, or hard-plastic building materials (💪)!

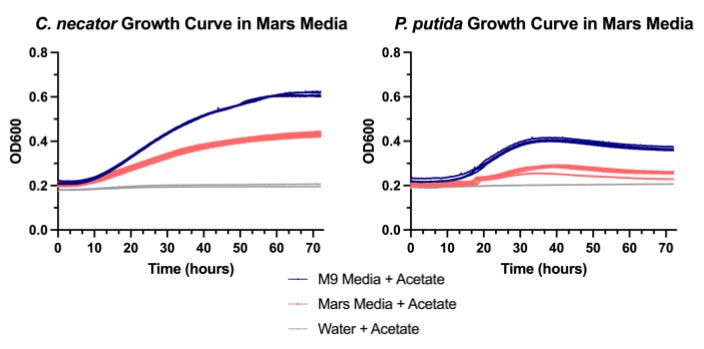

More specifically, we have identified two microbes, Cupriavidus necator H16 and Pseudomonas putida K2440, that grow in our recipe for Mars Regolith Media. In addition to the nutrients from regolith, they require a carbon source. We’ve chosen acetate, which can be easily sourced from the Mars atmosphere with electrocatalysis using a small-footprint device. Both organisms can produce PHA, a bioplastic that can be used for 3D printing. This is the first target for a viable bioprocess that can turn abundant Martian materials into useful products at unlimited scale.

Below, read about how we developed a framework to guide our strategy and decisions around building a bioprocess on Mars.

Developing a Mars Bioprocess Framework

🏗️ Infastructure needed for the bioprocess

When you are designing hardware for space, simpler is better. Less complexity means a lower chance of something breaking. Fewer, smaller devices means less upmass. For this reason, we need to be judicious in our choices about which devices we want to rely on to shield biology from the extreme environment of today’s Mars and generate growth conditions that permit reasonable yield.

Will there already be any existing infrastructure for us to ‘plug in’ to? The answer to this question depends on when we might flight test this biomanufacturing system relative to the first human mission. Although there’s no single agreed upon design for the first human mission to Mars, all reasonable mission architectures involve pre-placing infrastructure to generate rocket fuel for the ascent vehicle ahead of time, before the humans even launch from Earth. In particular, the idea is to pre-place equipment that can convert CO2 atmosphere and water into rocket fuel. Even if we end up flight testing a device before then, ice mining equipment and power generation are becoming mature technologies that could increasingly be obtained off-the-shelf. For this reason, we assume that there will be energy, water, and raw material extraction available as utilities on the surface of Mars.

When you are designing hardware for space, simpler is better.

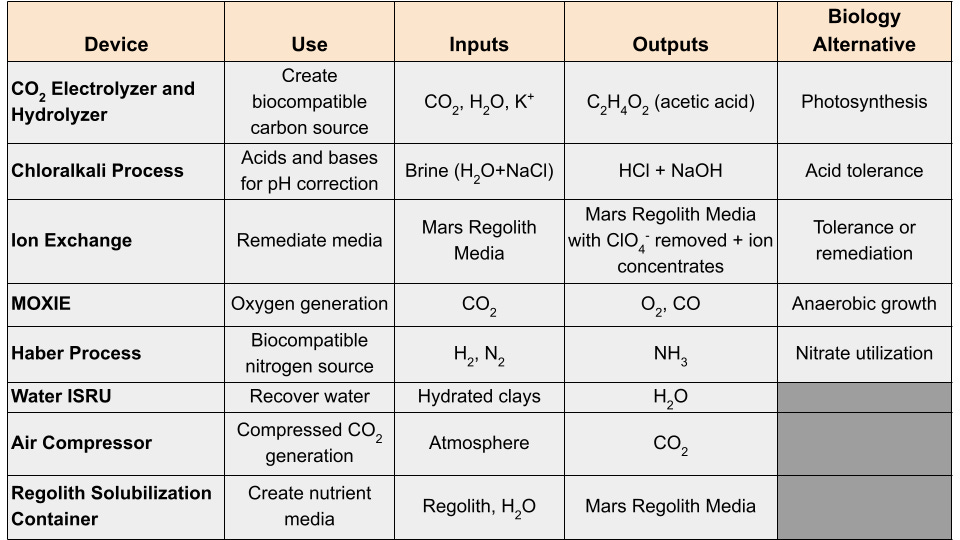

To map the space of possible hardware, we enumerated devices that are used in terrestrial biomanufacturing and devices that can solve challenges specific to Mars (excerpt below). In many cases, terrestrial biomanufacturing uses devices that improve yield, but that could in principle be substituted for a biological solution instead. For example, Earth often uses the Haber process to generate NH3 from atmospheric nitrogen because this is a type of nitrogen that is very easy for microbes to use. An alternative is to use NO3- directly, the type of fixed nitrogen in Martian regolith. The upside is that you require fewer devices; the downside is that microbes will grow more slowly.

💯 Growth in 100% Mars

All life as we know it requires carbon, nitrogen, phosphorus, and water to grow. A key to making biomanufacturing useful on Mars is unlocking growth that sources these key ingredients from raw Martian materials as much as possible. The space science community calls this in situ resource utilization (ISRU), and it is a key technology to enable scalable space missions.

In an earlier post, we defined a Mars Regolith Media that could be made by mixing 40 grams of regolith with a liter of water. Since then, we’ve learned how to grow two strains, Cupriavidus necator H16 and Pseudomonas putida K2440, using Mars media as their only source of nitrogen and phosphorous! (As expected, they do grow less well when sourcing these nutrients from Mars media due to the additional toxins that are present like salt, perchlorate, heavy metals, etc. Engineering is in progress to improve their growth in Mars media, stay tuned.)

The primary additional requirement is a source of carbon and energy that could be produced on Mars. One option is acetic acid, which can be produced with electrochemistry from compressed CO2 from the Martian atmosphere using a device the size of a microwave (see top row of the infrastructure table. These units exist, for example, from Lectrolyst. They’re also in use terrestrially.). Other options1 may include using photosynthetic organisms that can source their carbon directly from CO2 and gain energy from sunlight.

One major wrinkle we spent a long time debating is the challenge of controlling pH on Mars using in situ resources. Most microbes are only capable of optimal growth within a fairly narrow pH range, and as they metabolize food they often change the pH, quickly leaving the optimal range and halting growth. For this reason, if you want to achieve reasonable bioprocess yields, you almost certainly need a way to maintain pH within the optimal window. In the lab, it’s easy to do this with buffering chemicals like Tris, TES, etc., but these chemicals can’t easily be sourced on Mars without pretty extensive chemistry infrastructure. An alternative option is to use the chloralkali process to split Martian brines into a strong acid and base that can be added to your bioreactor as needed. If you are using acetic acid as your feedstock, another option might be to control pH exclusively with acetic acid addition: the metabolism of acetic acid raises the pH, which can then be lowered again by feeding with more acetic acid.

Together, all the essentials - carbon (air), nitrogen and phosphorus (dirt), and water (ice) - can be sourced directly from Mars, as can convenience chemicals to control pH.

All the essentials can be sourced directly from Mars.

💪 Bioproducts for Mars

The benefit of biomanufacturing with fully in situ resources is that it can, in principle, be conducted indefinitely. The longer the manufacturing device is operating on the surface of Mars, the more useful products it can accumulate in anticipation of human arrival. For this reason, the best first bioprocesses are ones for which essentially an infinite amount of the product would be useful. Want to tile the entire planet with greenhouses? Build them with biomaterials.

The best first bioprocess will be one that keeps it pretty simple.

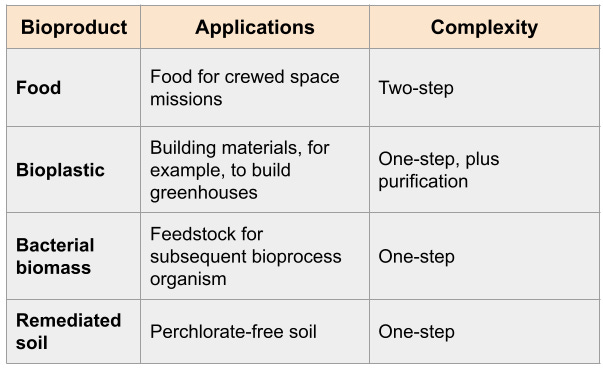

Another key feature we looked for is simplicity. There are many possible bioprocesses that require a series of organisms or intermediates. For example, production of food likely requires two steps: first, perchlorate remediation with a primary organism - second, conversion of biomass from the first step into edible protein using a secondary organism. The best first bioprocess will be one that keeps it pretty simple.

Putting it all together

Our ideal Mars bioprocess would 🏗️ require minimal infrastructure, 💯 only use Martian materials as input, and 💪 produce an impactful and valuable product. Making a good choice requires making tradeoffs between these conflicting priorities. Each specification interplays with all of the others, and the search space of bioprocesses and products is very large.

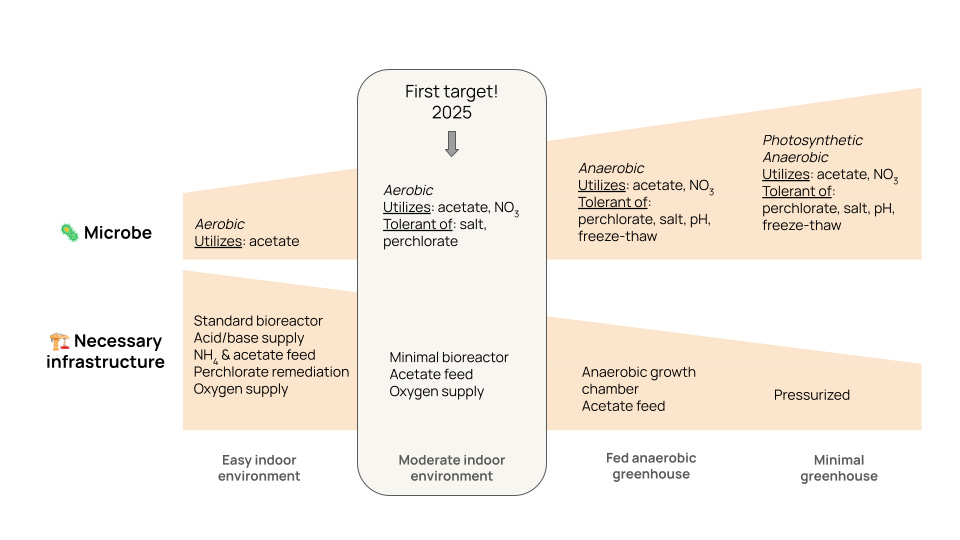

We’ve talked before about our engineering roadmap that envisions engineering microbes that tolerate increasingly challenging Mars-like conditions, starting with ‘indoor’ biomanufacturing of PHAs, proceeds to more complex organisms that can thrive in a minimal greenhouse, to future organisms that will form the base of the ecosystem on a Green Mars, likely beginning with photosynthetic organisms that grow in ice-covered lakes. Over time we can decrease our reliance on infrastructure to create favorable growth environments 🏗️, instead relying on the biology itself to tolerate extremes 🦠. Eventually, you decrease your infrastructure requirements to zero and have organisms that can grow entirely by themselves outdoors. Those are the organisms that can green the planet.

Our first target is a balance between asking too much and asking too little of the biology. We will challenge this microbe to tolerate toxins in Martian dirt and utilize its nutrients directly, but we won’t yet challenge it to tolerate daily freeze thaw or anaerobic growth, both of which would massively slow growth and reduce yield. This balance means our first microbe will de-risk key technologies needed for terraforming, while also still being practically useful for the first human mission.

Our 2025 focus is a single-microbe, single-step PHA production process operating in a controlled indoor environment. In 2026, we’ll begin bioprospecting for microbes that can grow in more ‘outdoor-like’ conditions—such as minimal greenhouses—and start exploring multi-step bioprocesses. For example, a photosynthetic microbe might convert CO₂ into biomass, which can then feed a heterotrophic microbe that produces a useful product. These layered processes expand the range of bioproducts we can make and begin to resemble full biomanufactories: systems where microbial processes are chained together to build, recycle, and sustain each other. In the long term, such multi-layered designs echo natural ecosystems—and may one day help make Mars a friendly place to live.

Our first microbe will de-risk key technologies needed for terraforming, while also still being practically useful for the first human mission.

Learn more

We are not alone in thinking about the grand possibilities of manufacturing with biology on Mars. Many others have taken on this roadmapping challenge and arrived at similar or different conclusions due to different assumptions about constraints. If you want to learn more, a few great reads include:

The case for biotech on Mars, 2020. A great rundown of how fairly traditional infrastructure-heavy biotech could be applied in a Mars context.

Towards a Biomanufactory on Mars, 2021. A great discussion of multi-step bioprocesses and how it could all fit together.

Microbial biomanufacturing for space-exploration, 2023. Surfaces some good information about the material requirements of space missions, including the expected quantities needed of plastics.

Many other analyses include use of human waste products as an essential component of the microbial feedstock. We’ve neglected this angle because there’s an inherently limited amount of human waste on Mars, making it unscalable. Still, biomanufacturing may be useful for waste management. A couple good reads to check out in this vein include this one and this one.

Also, congrats to Robin Wordsworth on his recent Science Advances paper! It dives into the challenge of scalable manufacturing of greenhouses on Mars using biomaterials. This paper is a great follow-on from Robin’s great 2019 paper about how transparent insulators like aerogels could replace having an atmosphere.

Reach out!

As we continue iterating on this framework and testing new bioprocess ideas, we would love to engage others working on biomanufacturing! We would especially love to connect with folks working in downstream processing of products, which similarly needs to be simplified and accomplished with in situ resources. Please comment below or reach out!

We are continually growing our team and have a current opening for a Senior Data Scientist. We will be opening a search for a laboratory automation engineer soon. If you want to stay updated on future job openings, please fill out this form.

There are a number of other potential sources of energy on Mars that could be utilized by more exotic organisms, but these are not realistic at the moment for high-yield bioprocesses. For example, chemolithotrophs grow very slowly and methanotrophs would require gas-exchange bioreactors that would be very challenging to use in a space mission context.

Cite as: Pioneer Labs Reports (2025). Our first target microbe for Mars, and how we chose it. figshare. Preprint. https://doi.org/10.6084/m9.figshare.29511008

How about Acetinobacter spp.? According to the following paper, one such species (Acinetobacter sp. NIIST (Genbank JX467695)) can reduce perchlorate: https://pubmed.ncbi.nlm.nih.gov/23872336/

“100mg/L of the compound was reduced completely in 48 h under anoxic condition.”

Would you mind talking more about what the carbon source might be in the future? It seems like acetate accomplishes a lot of roles (food for the microbes, buffering, easy to make). Are there carbon sources that would make the bioreactor more efficient despite being harder to make?